BACKGROUND

Anaerobic sequencing batch reactor (ASBR) is a high-rate liquid digestor system that uses a bioconversion process on low-solid, high-strength wastewaters to generate biogas and treat waste. It works in four phases: feeding in of substrate (manure, wastewater, etc.), the reaction between microorganisms and substrate by mixing the contents, settling of biomass (cessation of mixing and biogas production), and decanting of effluent fluid on top of settled solids. This cycling allows for the retention of the microflora and this system is a lower-cost approach to wastewater treatment currently being occupied by more expensive and less effective methods, such as sludge blanket reactors. Despite ASBR’s high efficiency and low cost, two main problems have prevented the development and field implementation of these setups: 1) material failure and complex design due to fluctuating reactor pressure, and 2) the inferior quality of decant liquid due to poor solid biomass settlement. There is a critical need for improvement of this digestor system to further its development to fill the niche for wastewater treatment and biogas production.

SUMMARY OF TECHNOLOGY

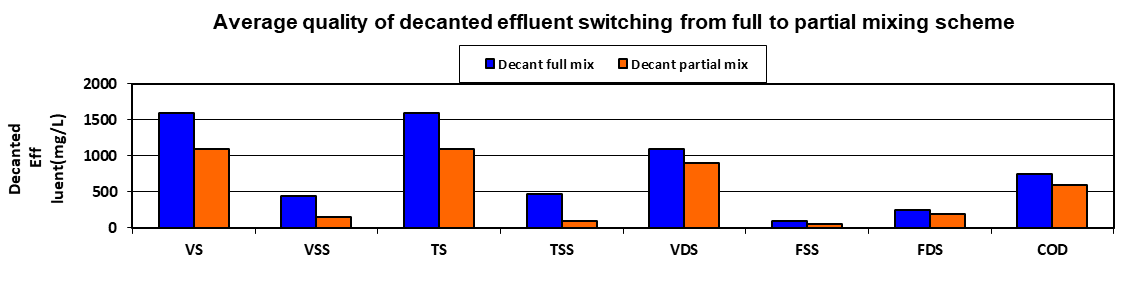

Researchers at OSU have developed a novel self-contained floating cover and operating system for ASBR digesters, improving ASBR design by combining all the functions of ASBR into one package. These unique improvements to ASBR design provide solutions to both problems associated with ASBRs. Constant pressure is maintained in the reactor vessel by using a weighted floating cover, preventing material failure with an accompanying design simplification. The decanting position withdrawal is related to the level of floating cover rather than to the vessel, which avoids the suction of suspended solids, improving effluent quality. Additionally, the operating system (housed in a unit that sits atop the cover) associated with the system allows for partial mixing in the reactor instead of full mixing, drastically improving effluent quality. Test data shows a reduction in several key parameters, such as the mass of total organic matter (VS), suspended organic matter (VSS), total solids (TS), total suspended solids (TSS), Volatile Dissolved Solids (VDS), Fixed Suspended Solids (FSS), Fixed Dissolved Solids (FDS), and chemical oxygen demand (COD) received by treatment components downstream of the digester (see figure).

POTENTIAL AREAS OF APPLICATION

- Animal production sector

- Mixing biodiesel production wastewaters with food, drink, human, and animal waste

- Pharmaceutical, personal care, and perfume manufacturing industries

MAIN ADVANTAGES

- Increased solid retention time

- Improved efficiency allowing for treatment of low solid, low strength waste streams

- Greater volatile suspended solids increase active biomass

- Partial mixing resolves microflora washout

STAGE OF DEVELOPMENT