BACKGROUND

As energy demand increases, efficiently produced biofuels such as ethanol will be preferred over fossil fuels due to their reduced costs. One such biofuel, butanol, has several technical advantages over ethanol including a higher energy density. Butanol is traditionally produced using molasses and starch in the acetone-butanol-ethanol (A-B-E) fermentation process. Recently, A-B-E fermentation has been derived from lignocellulosic biomass but suffers the drawbacks of low yield, low productivity, and inhibition by butanol.

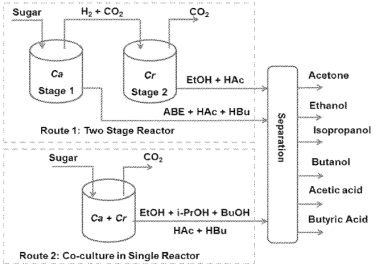

Unfortunately, the yield of butanol from biomass is poor because a large amount of the biomass used by solventogenic clostridium species produces uncaptured carbon dioxide (CO2) and hydrogen (H2), which can use the majority of the carbon of the sugar being processed. Most of these gas byproducts are released into the atmosphere, negatively impacting the process economy and the environment. Therefore, it is critical to improving ABE yields from renewable sources to make this process viable. To address this, an integrated conversion process using a novel co-fermentation process has been developed.

SUMMARY OF TECHNOLOGY

Researchers at OSU developed a novel biocatalytic conversion process for producing acetone, butanol, ethanol, and organic acids from sugars generated from various feedstocks such as starch and sugar crops, as well as lignocellulosic biomass. This unique technology uses a co-culture of microbes increasing the overall yield of alcohols by more than 25% over current methods, with butanol being the principal product. Other by-products, such as acetone, isopropanol, ethanol, acetic acid, and butyric acid can be produced as well. Another major benefit of this technology is the use of co-fermenting to decrease the CO2 and H2 waste. This novel process can be carried out in one reactor as a co-culture or in two reactors as monocultures to create multiple products

POTENTIAL AREAS OF APPLICATION

- Agriculture, food, pharmaceutical, environmental, and energy industries all use microorganisms to convert sugars and CO/CO2/H2 into diverse products.

- Biocatalytic conversion process to produce alcohols, ketones, and organic acids

MAIN ADVANTAGES

- Enhances overall yield of alcohol by more than 25%

- Sugar, starch, sugar crops, and lignocellulosic biomass can be used

- Unconverted gases (CO2 and H2) are recycled

- Optimal balance is maintained in mixed culture fermentations

- Converts wasted gas streams into useful products (reduces CO2 emissions).

STAGE OF DEVELOPMENT

This technology is currently available as a prototype