BACKGROUND

Liberation of gases from liquids is of primary importance to numerous natural and industrial processes such as boiling, cloud formation, volcanic eruption, food and beverage production, biological, mineral, nuclear, pharmaceutical, electrochemical, and petroleum production and refining. Natural gas evolution in saturated oil reservoirs and gas separation in wellbores and surface facilities are some examples of gas liberation from supersaturated liquids in the petroleum industry. Properly controlling the separation of gases in these settings represents a significant material cost. Gas-liberation kinetics influence production strategies and the associated equipment-design criteria, so critical insights into these processes are necessary for petroleum production operations.

SUMMARY OF TECHNOLOGY

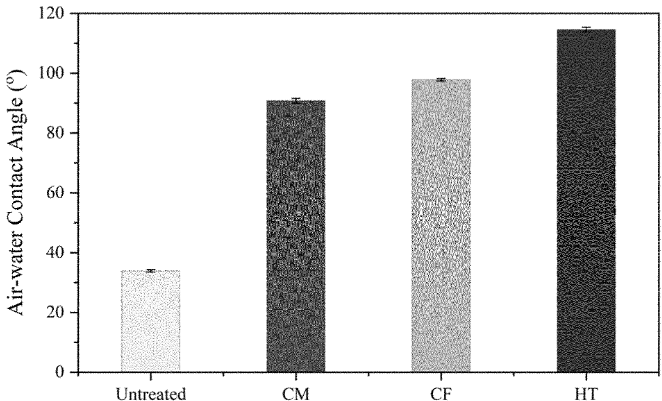

OSU researchers have developed techniques using non-wetting or wetting surfaces to promote or hinder separation of gas from solution in a liquid. Dissolved gas separation involves bubble nucleation, which commonly occurs on the surface of the container and/or any other solid surfaces in touch with the liquid. Dissolved gas separation is promoted when the surface is not wetted by the liquid or heterogeneous bubble nucleation. The use of a liquid-phobic coating increases the gas/liquid contact angle (see figure) and reduces the pressure/energy needed to separate gas from liquid. The technique focuses on the use of pressure instead of heat application. Furthermore, bubble nucleation suppression by using wetting surfaces can facilitate supersaturated solutions of gas or gases in a liquid. These methods drastically increase the efficiency of separating dissolved gases, providing a clear benefit to not only the energy industry, but also produced water treatment, as well as the food and beverage industries.

POTENTIAL AREAS OF APPLICATION

- Produced Water Treatment

- Energy Production

- Food and Beverage industries

- Ethanol production for food and fuel applications

- Supersaturation for production of crystals

MAIN ADVANTAGES

Improves separation efficiency according to application reducing energy requirements Lower pressure requirements and energy consumption

- Separation of natural gas from oil during refining.

- Ethanol production for food and fuel applications.

- Supersaturation for production of crystals.

STAGE OF DEVELOPMENT

Prototype