BACKGROUND

Harnessing solar energy as a replacement for fossil fuels is an important avenue in addressing climate change. An exemplar issue facing the utility and scalability of this energy source is solar-to-heat conversion efficiency in photothermal layers. More specifically, both reflectance/transmission heat loss and convection/radiation heat transfer losses need to be minimized. However, these losses are determined by the temperature gradient in the photothermal layer material and its thickness, respectively. I.e., minimizing thickness minimizes thermal resistance, but will compromise absorbed power, and trying to increase that will result in heat loss due to temperature gradient. Thus, there is a distinct need to increase the absorption ability of photothermal layers in order to achieve maximum absorbed power at a minimum thickness.

SUMMARY OF TECHNOLOGY

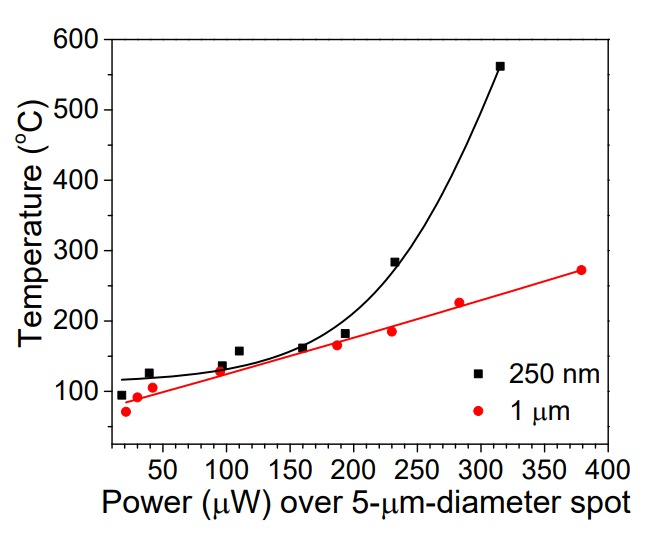

Researchers at OSU have developed a solar or simulated solar thermal absorber, consisting of a dispersion of high photothermal efficiency Mie-resonator nanoparticles in liquids or solids depending on the application, such as an ionic liquid, oil, water, thermoset polymer, and glass. Mie-resonator nanoparticles function similarly to cavity resonators; they confine photons in a nanoscale volume by their high refractive index (n > 2.5). Test data for this technology have shown that isolated Cu2O nanoparticles (250 nm) in air can reach a temperature of 550 °C under low laser radiation of ~5 mW (see plot below). In addition to Cu2O, other earth abundant materials may be employed to synthesize Mie-resonator nanoparticles, such as CuO, Fe2O3, FeS2, MoS2, Si, and VO2. The high efficiency Mie-resonator nanoparticles solar or simulated solar thermal absorbers can be exploited in water desalination/distillation, electric power generation, thermochemical processes, indoor heating, and sanitization.

POTENTIAL AREAS OF APPLICATION

- Solar electricity generation

- Water desalination/distillation

- Thermochemical processes

- Portable heating

- Sanitization

MAIN ADVANTAGES

- Allows for minimizing absorber layer thickness, dropping thermal resistance and heat loss

- Tunable to match solar spectrum

- Nanoparticles dispersible on various host materials and can coat on surfaces

- Made of Earth-abundant materials

- Low-cost and scalable manufacturing via solution/colloidal chemistry

STAGE OF DEVELOPMENT