BACKGROUND

Catalyst poisoning - defined as the loss or reduction of catalytic activity due to contaminants binding to or chemically altering binding sites - remains a major obstacle in the production of renewable hydrocarbon and biofuels. Among these contaminates, phosphorus is particularly troublesome. It originates from natural phospholipids present in renewable feedstocks and forms stable, irreversible compounds on catalytic surfaces. This leads to rapid deactivation and significantly increases operational costs. Conventional methods for assessing phosphorus contamination are often slow, expensive, and labor-intensive, highlighting the urgent need for fast, accurate, and real-time detection technologies in renewable energy processes.

SUMMARY OF TECHNOLOGY

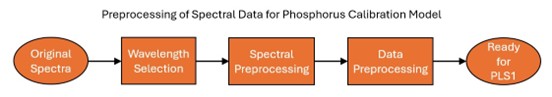

Oklahoma State Researchers utilized data preprocessing and the spectral range that captures or contains phosphorous/phospholipid related chemistry in combination with infrared spectroscopy to rapidly and accurately quantify phosphorus in renewable fuel production streams. By selecting the appropriate spectral ranges, spectral interferences from complex feedstock matrices are diminished, significantly enhancing the precision and robustness of phosphorus detection. This methodology enables real-time, online monitoring of phosphorus contamination, allowing immediate mitigation strategies and optimal catalyst management. As a result, this technology offers substantial improvements in process efficiency, catalyst lifespan, and cost savings for renewable hydrocarbon production.

POTENTIAL AREAS OF APPLICATION

- Agricultural Waste Processing Industry

- Algae-Based Biofuel Production

- Chemical Processing Plants

- Waste Cooking Oil Recycling Operations

- Oil & Gas Exploration Companies

- Industrial Catalyst Manufacturing

MAIN ADVANTAGES

- Real-Time Monitoring Analysis

- PLS Modeling for Precise Phosphorus Detection

- Prevents Unexpected Catalyst Deactivation

- Rapid Phosphorus Identification

- Biofuel Production & Testing

- Heavy Metals Removal

- Natural Gas to Fuels

- Mid IR Spectral Data Contamination Detection

STAGE OF DEVELOPMENT